Products

- Reactors[3]

- Pressure Vessels[1]

- Other Pharmaceutical Machinery[1]

- Beverage Processing Machinery[1]

- Chemical Process Equipment Parts[6]

- Heat Exchanger[7]

- Chemical Product Machinery[10]

- Separation Equipment[3]

- Drying Equipment[5]

- Chemical Storage Equipment[2]

- Chemical Product Machinery Parts[1]

- Other Packaging Materials[1]

- Other Lab Supplies[5]

- Other Refrigeration & Heat Exchange Equipment[1]

Contact Us

- Contact Person : Mr. zhu stephen

- Company Name : Wuxi Jiesheng Environment Chemical Equipment Co., Ltd.

- Tel : 86-0510-85181368

- Fax : 86-0510-85186582

- Address : Jiangsu,wuxi,No.8 Hengshan Road, Xuelang, Binhu, Wuxi, Jiangsu, China

- Country/Region : China

- Zip : 214125

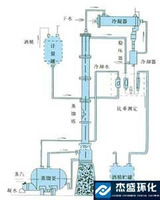

Ethanol Distiller(can reclaim alcohol)

Product Detailed

Related Categories:Separation Equipment

Alcohol recovery tower, volume:640~3200L, HTA: 3~26SQM, Condensing area:5~45SQM, material: SS or CS

Use:The equipment is used for reclaim the attenuant alcohol in pharmaceutical ,foodstuff ,light and chemical industry .And also used for distill carbinol or others .The equipment can distill about 30°attenuant alcohol to 90~95°alcohol ,according to user's requirements .Main Features:This equipment adopts high efficient stainless steel corrugated fillings,all made of stainless steel in order to ensure the alcohol cant be polluted.The tower adopts knock-down V style pipe,so it is convenient for heating ektexine and cleaning the wall wiall of the tower.The equipment adopts two styles of external and internal heating,the clients may choose it according to the pratical needs.Main Technique Parameter:| Standard Requirement | JH200 | JH300 | JH400 | JH500 | JH600 | JH800 |

| (L) | 640 | 1220 | 1450 | 2300 | 2500 | 3200 |

| Tower Volume | ||||||

| (mm) | 6000 | 7000 | 7000 | 7000 | 7500 | 7500 |

| Tower Height | ||||||

| (L) | 300 | 400 | 650 | 800 | 1000 | 1500 |

| High-level Tank Volume | ||||||

| (m2) | 5 | 9 | 11 | 18 | 25 | 45 |

| Condensing Area | ||||||

| (m2) | 1 | 1.5 | 2.2 | 4 | 6 | 8 |

| Cooling Area | ||||||

| (m2) | 3 | 6 | 6.5 | 10 | 15 | 26 |

| Heat Exchange Area | ||||||

| (kg/h) | 45-50 | 90-100 | 150-160 | 280-300 | 420-440 | 600-620 |

| Reclaiming Capability | ||||||

| (kg) | 1100 | 1900 | 2300 | 3800 | 4500 | 6800 |

| Device Weight | ||||||

| (mm) | 2300×700 | 2600×800 | 2500×1000 | 3000×1200 | 3500×1400 | 4200×1800 |

| Outer Size (Length * Width * Height) | ×7300 | ×7500 | ×9000 | ×9000 | ×1000 | ×14000 |

| Reclaiming Density (%) | >90 | |||||

| Stuffing Method | Kelapak or Stainless Steel Packed of Column | |||||

| Vessel Sort | I Sort |

Ethanol Distiller(can reclaim alcohol)